Flake graphite, a natural graphite material that has a distinctly flaky or platy morphology with it carbon atoms linked together in an arrangement in a hexagonal structure. Natural flake graphite are processed from graphite ore, crushed and milled into big and small flake which further purify by a flotation system. It has perfect crystallization, good toughness despite thin flake and yet flexible, it has floatability, Self-lubricating and mouldability are better than other graphite. It’s also resistant to thermal shock, acid, alkali, corrosion and high-temperature. Flake graphite have a high thermal and electrical conductivity thus make suitable for many conductive applications. ... More>

Flake graphite are further grinded by a high-speed grinder, ramon miller, airflow miller and other advanced grinding equipment to produce micronized graphite with size ranging from 5 to 80 micron. Micronized graphite are extensively used in many industries to produce carbon products, lubrication materials, fertilizer catalyst, pencil lead, metallurgy additive powder, as well as filler for improver of rubber and plastic composites. ... More>

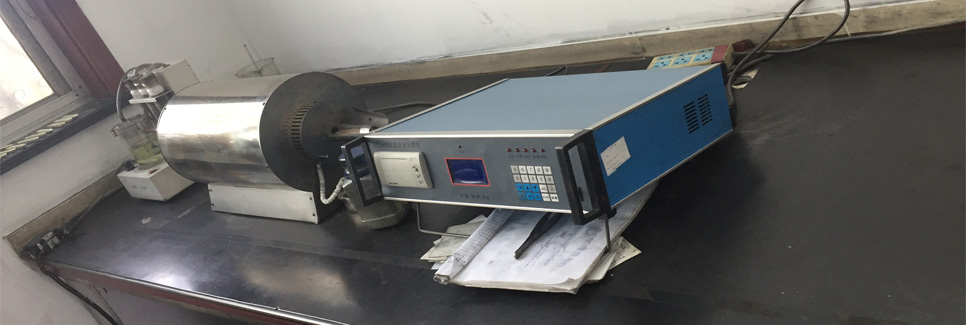

High purity flake graphite are further processed through a special chemical modification call intercalate process. Chemical is inserted into the spaces between the graphene planes during the Special chemical process. This intercalate process enable processed graphite to expand many times of it original size when under high temperature with an expansion ratio of 100~500ml/g. Its shape would change from flake to worm like, turn flexible and porous with a larger specific surface area and stronger absorption capacity. These worm like graphite could tabling among themselves, which increases their flexibility, rebound elasticity and machinability, so they are excellent material to produce flexible graphite sheet and various kinds of sealing elements. It can also be used as lubricating filler, heat preservation additive for metallurgical industry, battery adsorbent material, halogen free flame-retardant additive and so on. ... More>